In the ever-evolving landscape of electronics, efficient thermal management is paramount to ensure optimal performance, longevity, and reliability of devices. Custom heat sinks, particularly extruded profiles heatsinks, have emerged as a popular and highly effective solution for dissipating heat generated by electronic components. Their versatility, cost-effectiveness, and excellent thermal properties make them a preferred choice for a wide range of applications. This blog delves into the manufacturing process, advantages, and successful applications of custom heat sinks and extruded profiles heatsinks, highlighting why they should be your go-to solution for thermal management needs.

Table of contents:

The Manufacturing Process of Extruded Aluminum Heatsinks Explained

Top 3 Advantages of Extruded Profiles Over Other Heatsink Types

Case Studies: Successful Applications of Extruded Heatsinks in Electronics

The Manufacturing Process of Extruded Aluminum Heatsinks Explained

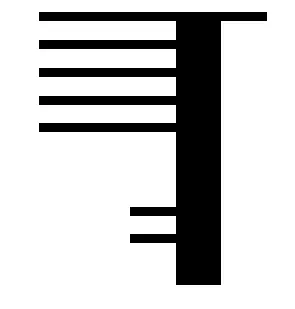

The process of creating extruded aluminum heatsinks is a marvel of engineering, allowing for the creation of complex geometries with high precision. It begins with heating an aluminum billet to a malleable state. This softened aluminum is then forced through a die, a shaped opening that determines the final profile of the heatsink. This extrusion process allows for intricate fin designs and complex shapes, maximizing the surface area available for heat dissipation. Once extruded, the heatsink profile is cut to the desired length and may undergo further machining or surface treatments to enhance its thermal performance or corrosion resistance. Anodizing, for example, creates a protective layer that improves durability and emissivity. This efficient and repeatable manufacturing process makes extruded profiles heatsinks a cost-effective solution for high-volume production.

Top 3 Advantages of Extruded Profiles Over Other Heatsink Types

Extruded profiles heatsinks offer several compelling advantages over other heatsink types, making them a superior choice for many thermal management applications. First and foremost, their design flexibility is unmatched. The extrusion process allows for the creation of intricate fin patterns and complex geometries that maximize surface area and optimize airflow. This level of customization ensures efficient heat dissipation tailored to specific component requirements. Secondly, extruded profiles heatsinks are remarkably cost-effective, especially for high-volume production. The extrusion process is efficient and scalable, making it an economical solution for managing heat in a wide range of electronic devices. Finally, aluminum, the most common material used in extrusion, offers an excellent balance of thermal conductivity, weight, and cost. Aluminum's lightweight properties are particularly beneficial in applications where weight is a critical factor. These combined advantages make extruded profiles heatsinks a winning solution for thermal management challenges.

Case Studies: Successful Applications of Extruded Heatsinks in Electronics

The versatility of extruded heatsinks is showcased in their diverse applications across various industries. In the power electronics sector, they are crucial for cooling high-power semiconductors in power supplies, inverters, and motor drives. Their ability to efficiently dissipate heat ensures the reliable operation of these critical components. In the LED lighting industry, extruded profiles heatsinks play a vital role in maintaining the optimal operating temperature of LEDs, extending their lifespan and maintaining consistent light output. The compact and efficient designs allow for seamless integration into various lighting fixtures. Furthermore, in the computer and server industries, extruded aluminum heatsinks are used to cool CPUs, GPUs, and other heat-generating components, ensuring stable performance and preventing thermal throttling. These case studies demonstrate the adaptability and effectiveness of extruded profiles heatsinks in diverse electronic applications.

In conclusion, extruded profiles heatsinks offer a compelling combination of design flexibility, cost-effectiveness, and excellent thermal performance, making them an ideal choice for a wide range of thermal management needs. From power electronics to LED lighting and computer systems, their versatility and efficiency have been proven time and again. Consider the benefits of extruded profiles heatsinks for your next thermal management challenge and experience the difference they can make in ensuring the reliability and performance of your electronic devices. Choose wisely, choose efficiency, choose extruded profiles heatsinks!

Comments

Post a Comment