Table of contents:

Understanding the Superiority of Tungsten Carbide in Industrial Applications

Key Factors to Consider When Selecting Tungsten Carbide Rods Suppliers

Comparing Tungsten Carbide Welding Rods to Traditional Welding Materials

Real-World Applications: Success Stories from Industries Using Tungsten Carbide Rods

Understanding the Superiority of Tungsten Carbide in Industrial Applications

Tungsten carbide has long been recognized as one of the most versatile and durable materials for industrial use. Its impressive combination of hardness and wear resistance makes it ideal for applications that demand strength and longevity. Whether in mining, construction, or manufacturing, tungsten carbide rods have set the standard for performance in harsh environments. Unlike conventional materials, tungsten carbide is designed to withstand extreme abrasion and high temperatures, ensuring reliable operation under challenging conditions. Furthermore, its enhanced density and strength enable precision performance in critical applications where consistency is vital. Its durability also reduces downtime and maintenance costs, making it a highly cost-effective solution. With such advantages, tungsten carbide stands apart as a valuable material for heavy-duty industrial applications.

Key Factors to Consider When Selecting Tungsten Carbide Rods Suppliers

Selecting the right tungsten carbide rods supplier is crucial to ensure quality and reliability. A dependable supplier guarantees products that meet the highest industry standards, which is essential for applications requiring precision and durability. Look for suppliers with a proven track record of expertise in manufacturing tungsten carbide products. Check whether they provide thorough quality assurance and testing processes to ensure consistent performance. Additionally, the availability of customizable options, such as size and composite structure, can be an essential factor for meeting specific application requirements. Suppliers should also offer excellent customer service and timely delivery to ensure smooth operations. Finally, sourcing from trusted tungsten carbide rods suppliers provides peace of mind, as you'll receive high-performing rods tailored to your industrial needs. Always research and compare suppliers to make an informed choice.

Comparing Tungsten Carbide Welding Rods to Traditional Welding Materials

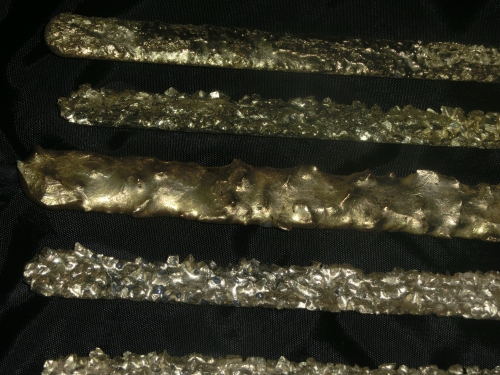

Tungsten carbide welding rods outperform traditional welding materials in numerous critical aspects. Their superior wear resistance and hardness make them a preferred choice for industries requiring durable solutions, such as petroleum drilling, coal mining, and construction. Unlike traditional welding materials, tungsten carbide welding rods are engineered to endure severe abrasion and impact, enabling them to withstand the rigors of high-stress environments. The exceptional hardness of tungsten carbide ensures that welded surfaces remain intact and functional for extended periods, even under abrasive conditions. This leads to fewer replacements and reduced maintenance costs, delivering long-term savings. Additionally, these rods offer enhanced versatility, making them suitable for welding tools, drilling pipes, and construction equipment. Overall, tungsten carbide welding rods represent a significant upgrade over conventional materials for industrial welding applications.

Real-World Applications: Success Stories from Industries Using Tungsten Carbide Rods

Real-world success stories highlight the extensive applications of tungsten carbide rods across various industries. The mining industry, for example, relies on tungsten carbide composite rods to resist the relentless abrasion and impact of drilling operations. These rods have significantly enhanced performance and reduced operational downtime for several companies, improving productivity and profitability. Similarly, the construction sector benefits from tungsten carbide rods in heavy machinery, where their strength and wear resistance extend the life span of critical components. The cutting and manufacturing industries also leverage tungsten carbide for precise operations, such as cutting tools and end mills, where accuracy and durability are paramount. These success stories underline the material's versatility and reliability across demanding industrial environments. By partnering with high-quality tungsten carbide rods suppliers, businesses can achieve improved efficiency, reduced costs, and better performance.

Tungsten carbide rods have cemented their place as a vital material across various industries due to their unmatched durability, wear resistance, and versatility. Whether in mining, construction, or precision manufacturing, their ability to withstand demanding conditions while maintaining peak performance makes them an essential investment for businesses seeking reliability and efficiency. By utilizing high-quality tungsten carbide rods, companies can not only enhance operational productivity but also significantly reduce maintenance and replacement costs. The widespread application and proven success of tungsten carbide rods highlight their crucial role in driving progress and innovation in industrial sectors worldwide.

Comments

Post a Comment