Table of contents:

How Pulp Molding Machines Enable Eco-Friendly Packaging at Scale

The Benefits of Switching to Sustainable Egg Packaging Solutions

Why Manufacturers Are Investing in Molded Pulp Production Lines

How Pulp Molding Machines Enable Eco-Friendly Packaging at Scale

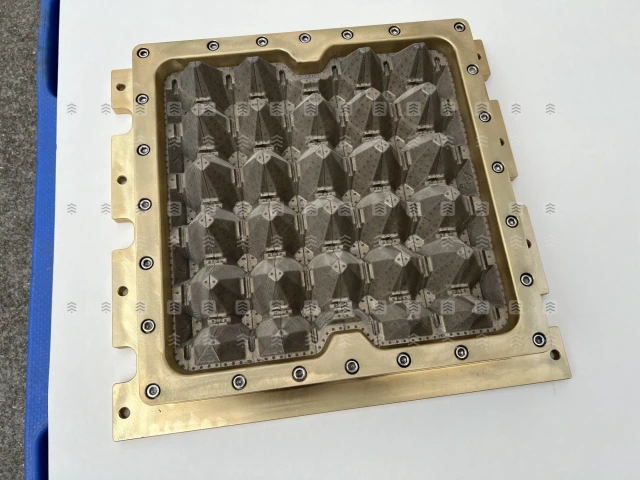

Pulp molding machines are at the heart of sustainable packaging innovation. These machines transform natural fibers such as recycled paper, cardboard, and agricultural residues into durable and biodegradable packaging products. They are designed to efficiently produce custom molded pulp packaging with minimal waste and energy consumption, making them a crucial asset for eco-conscious manufacturers. These machines ensure businesses can meet the growing consumer demand for sustainable products without sacrificing scalability or quality. Pulp molding machine manufacturers, play an integral role in facilitating the global shift towards eco friendly food packaging. For instance, Dwellpac’s Eco Egg Tray Mold exemplifies how expertly designed machinery can produce high-quality molded fiber egg cartons while maintaining sustainable production standards. This innovative mold not only ensures durability and precision in every carton but also supports eco-friendly practices by utilizing renewable materials and minimizing waste during the manufacturing process. It’s a perfect blend of efficiency, quality, and environmental responsibility.

The Benefits of Switching to Sustainable Egg Packaging Solutions

Sustainable egg packaging solutions like molded fiber egg cartons are not only ecologically responsible but also offer significant benefits to both manufacturers and consumers. Molded fiber egg cartons are biodegradable, compostable, and perfect for reducing harmful plastic waste. By transitioning to custom eco friendly packaging, businesses can cater to a market that is increasingly inclined towards sustainability, enhancing both brand image and customer loyalty. Additionally, these cartons provide adequate cushioning to maintain the quality of the eggs during transportation. Manufacturers that use molded pulp egg packaging can leverage consumer preferences for eco-friendly products while appealing to wholesale buyers seeking sustainable solutions. Companies will also find that sustainable egg packaging aligns with regulatory pressures and global initiatives to reduce plastic use. With options for customization and high-volume production, suppliers prove that environmental stewardship can go hand-in-hand with performance.

Why Manufacturers Are Investing in Molded Pulp Production Lines

The rise in consumer demand for eco-friendly food packaging has driven manufacturers to invest heavily in advanced molded pulp production lines, which are designed to create biodegradable and compostable packaging alternatives. This shift is fueled by growing market opportunities as businesses adapt to meet consumer preferences for sustainable products, alongside increasing global commitments to reducing plastic waste and environmental impact.Custom molded pulp packaging allows businesses to deliver tailored solutions that meet specific needs, such as molded fiber egg cartons for agriculture or specialized trays for industrial packaging. Investing in production lines featuring high-performance aluminum molds, like those offered by Dwellpac, provides not only precision and consistency but also the ability to scale operations efficiently. Furthermore, these production lines reduce reliance on non-renewable materials by replacing plastic with biodegradable alternatives. Molded pulp manufacturers benefit from reduced production costs, enhanced brand reputation, and the ability to position themselves as industry leaders in sustainability. These investments reflect a growing recognition that prioritizing eco-conscious practices is not just beneficial for the planet but also for long-term profitability and market relevance.

The shift towards sustainability in manufacturing is no longer a mere trend but a critical necessity for businesses aiming to thrive in a competitive and environmentally conscious marketplace. By adopting innovative approaches, such as molded pulp production, companies can achieve a balance between profitability and ecological responsibility. This proactive commitment to sustainable practices not only meets the growing expectations of environmentally conscious consumers but also plays a crucial role in reducing environmental impact. By prioritizing eco-friendly initiatives, businesses can contribute to preserving natural resources, reducing carbon footprints, and ensuring a healthier, more sustainable planet for future generations to thrive.

Comments

Post a Comment