Table of contents:

The balance of glass fiber and epoxy resin in delivering flexible yet strong surf fins

How honeycomb core surf fins adapt to different surfing conditions and rider weights

Rider experience improvement through selecting the right surfboard fin system compatibility

The balance of glass fiber and epoxy resin in delivering flexible yet strong surf fins

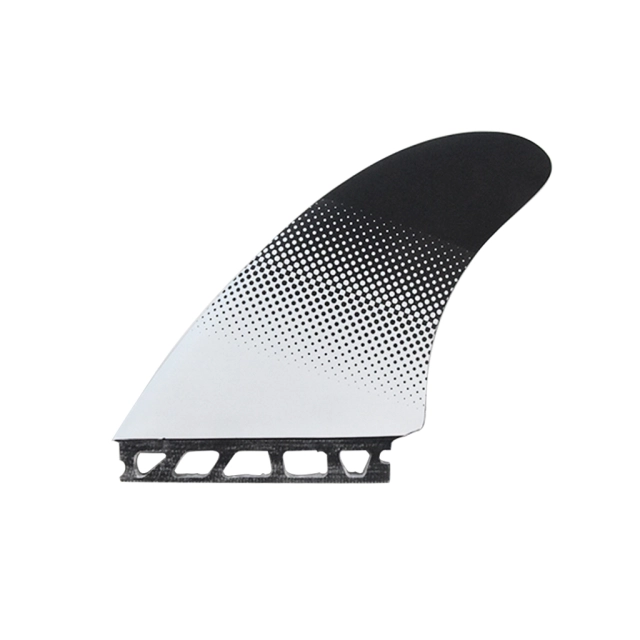

Material composition largely defines the character of a surfboard fin, especially the balance between flexibility and rigidity. Glass fiber provides the structural backbone, offering the stiffness needed for drive and acceleration out of turns. Epoxy resin, on the other hand, acts as the binding agent that holds the fibers together while contributing to the fin's overall flex pattern. Achieving the right ratio is crucial. A fin with too much glass can feel rigid, while one with too much resin might feel overly flexible. The F00546 fins, with their composition of 30% glass fiber and 20% epoxy resin, strike an effective balance. This combination, achieved through a precise resin transfer molding process, creates a fin that offers reliable drive without sacrificing responsiveness. For shops looking for a consistent wholesale surfboard fin supply, this predictable performance is a key selling point, ensuring customers get a dependable product. This material science translates directly to a better feel in the water.

How honeycomb core surf fins adapt to different surfing conditions and rider weights

A honeycomb core significantly influences a fin's weight and flex characteristics, making it adaptable to a wide spectrum of waves and surfers. This hexagonal internal structure significantly reduces the fin's weight compared to solid fiberglass alternatives, resulting in a livelier feel underfoot. The F00546 fins from CIMI Sports utilize a 50% honeycomb core, which is key to their versatility. This design provides a medium flex pattern that performs predictably across conditions, from small, mushy waves to more powerful, clean faces. This adaptability is also tied to the rider's weight, which is why CIMI offers sizes from XS for surfers under 55 kg to XL for those over 85 kg. A lighter rider can properly engage the flex of a smaller fin, while a heavier rider gets the support of a larger size. Any business looking for wholesale surf fin options can appreciate this thoughtful approach to sizing, a hallmark of a proficient surf fin manufacturer.

Rider experience improvement through selecting the right surfboard fin system compatibility

A fin system—the type of plug or box installed in the board—is a critical detail that can be a source of frustration for many surfers. There is nothing more disappointing than acquiring a new set of fins only to find they are incompatible with one's board. A forward-thinking surfboard fin manufacturer addresses this by offering products that cater to the market's diverse standards. The F00546 Honeycomb fin, for example, is available for all major systems, including the popular single tab and double tab configurations, as well as the standard box fin system. This broad compatibility ensures that a wide range of surfers can benefit from the fin's design. For retailers building their inventory with wholesale surfboard fin products, this versatility simplifies stock management and satisfies a larger customer base, reinforcing the value of partnering with a comprehensive supplier like CIMI Sports.

The right set of fins transforms a surfboard into a responsive tool for riding waves. The thoughtful combination of a honeycomb core with glass fiber and the availability of multiple sizes from XS to XL demonstrate a deep understanding of surfer needs. These design elements are the foundation of a more enjoyable experience on the water. For businesses seeking a reliable surf fin manufacturer for wholesale or OEM partnerships, selecting a supplier focused on such crucial details ensures their customers receive quality and performance with every session.

Comments

Post a Comment